Automatic Magnetic Filter Package

Model AMF_xxyy

Iron impurities in fluids can have negative consequences on product quality and equipment longevity across various industries, including steel production and the manufacturing of diverse products like hydraulic oils, liquid chemicals, coolants, ceramics, and more. One of the methods for removing these iron contaminants from fluids is through membrane or barrier filters, which leave particles smaller than five microns in the fluid.

These particles can negatively affect fluid performance or product quality and lead to bacteria buildup. Another worldwide solution is the use of magnetic filters, which are not only environmentally friendly and efficient for industrial applications and processes, but also provide an effective way to remove iron particles from fluids, even particles smaller than one micron.

Magnetic filtration is a method that removes iron particles from products in liquid or slurry form and can be used in most environments contaminated with iron and paramagnetic substances.

In terms of environmental compatibility, magnetic filter equipment does not generate pollution. The collected contaminants in the magnetic trap are recyclable, meaning none of the polluted materials end up in landfills. Additionally, the fluid being filtered retains its essential properties, thereby extending its service life.

The working principle of a magnetic filter is based on using high-intensity magnetic rods that are installed at the desired location or along the fluid or slurry (liquid) path. The magnetic field created by these rods attracts any iron particles to the filter rods, capturing them in a magnetic trap.

Gimeh Sanat Sepahan, with nearly three decades of experience in providing parts and equipment for the steel industry and its familiarity with the challenges faced in steel production lines, has developed and implemented the AMF Automatic Magnetic Filter Package designed to operate under harsh industrial environments, particularly in steel production. This report provides an overview of the specifications and capabilities of the device.

AMF Magnetic Filter

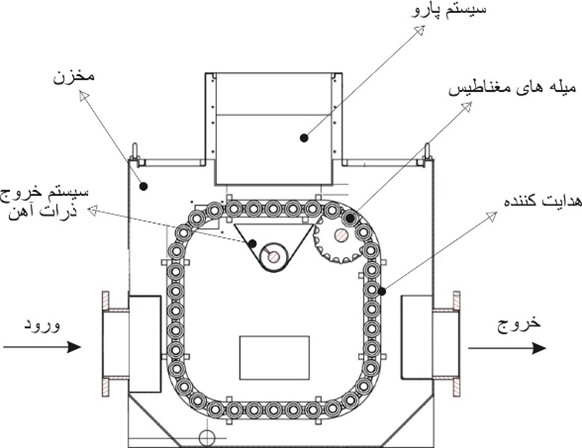

The AMF Automatic Series Package from Gimeh Sanat Sepahan includes rods with high magnetic field strength that attract iron particles present in the fluid. After the magnetic rods capture the iron particles, they are automatically cleaned, and the iron particles are directed out of the package to be discharged into the designated containers. The AMF series can be designed and manufactured in various sizes, applications, and capacities based on customer requirements.

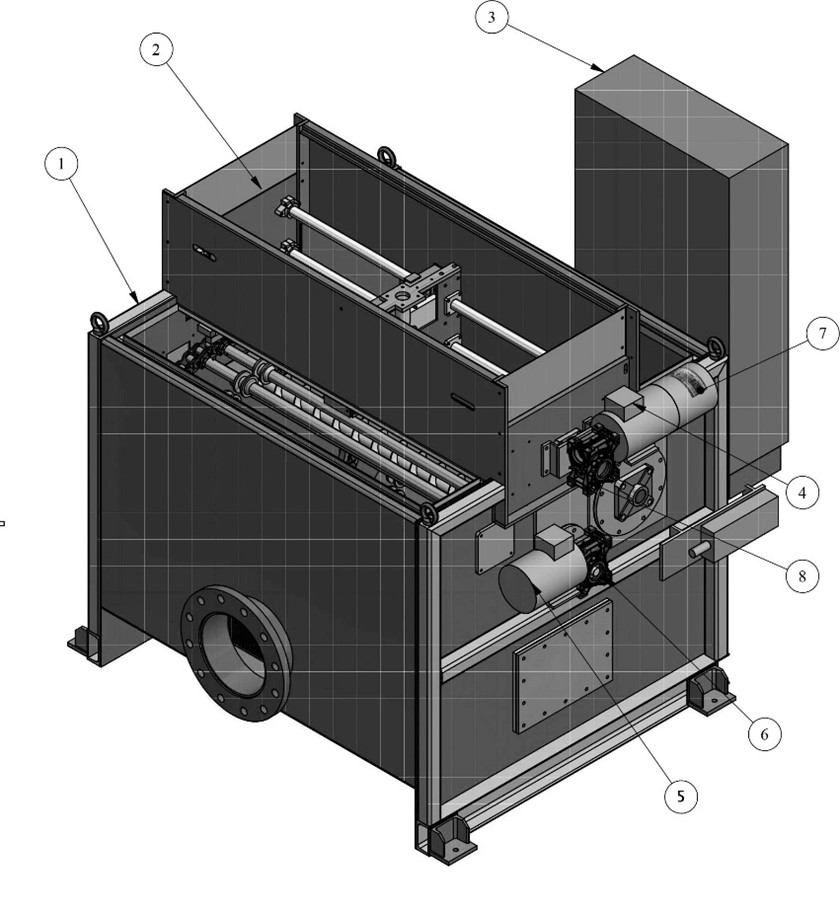

The AMF package consists of the following components:

- Fluid inlet

- Fluid outlet

- Storage tank

- Magnetic rods

- Magnetic rod cleaning system

- Intelligent control and protective systems

This system is designed to efficiently remove iron particles from fluids in a continuous and automated manner, making it ideal for use in industries such as steel production and other fluid-based manufacturing processes.

- Fluid Inlet and Outlet Tank

- Magnetic Rod Cleaning System

- Control System

- Electric Motor

- Electric Motor

- Gearbox

- Electric Brake

- Gearbox

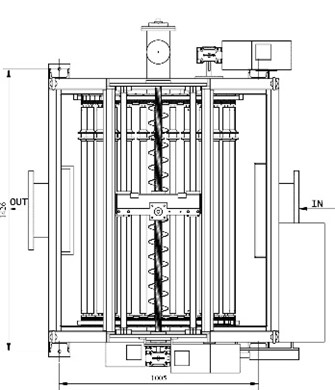

The fluid is directed into the magnetic rod tank through the inlet flange, and the magnetic rods automatically rotate inside the fluid, attracting iron particles. These particles are then transferred from the tank to the cleaning paddle area through rotational motion. The paddle cleans the iron particles attracted to the magnetic rods, and the rods are then directed back into the tank to repeat the process of attracting iron particles (Figure 2).

The cleaned particles from the magnetic rods are then directed out of the device through a chute and auger, while the fluid, free of iron particles, exits the device from the outlet. The entire process is automatic and can be repeated with pre-set time and speed control, without the need for an operator during operation.

One of the main advantages of the MGM magnetic filter is that it does not create any obstruction to productivity or cause a reduction in fluid flow. This is because the fluid passes through without any components that would hinder its passage or reduce its flow rate. In other words, even though the filter is ONLINE in the fluid flow circuit, the flow rate is not affected by the filter, whether the system is operating or turned off.

Advantages and Features of the AMF Magnetic Filter

By

using the AMF filter, iron contamination in the fluid is collected and the fluid recovery rate is increased, which will result in the following benefits:

- Improved product quality by reducing fluid contamination

- Reduced costs of equipment and spare parts related to the fluid

- Reduced water consumption

- Lower disposal costs

- Environmentally friendly and sustainable

Types of AMF Packages

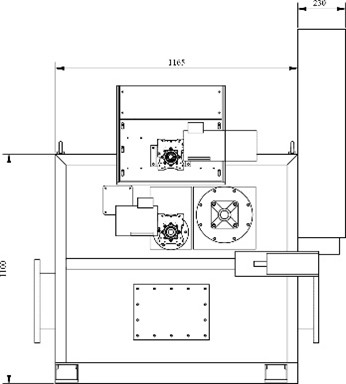

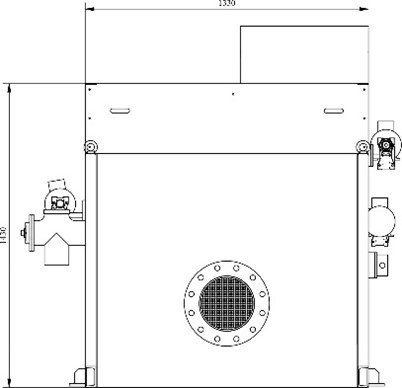

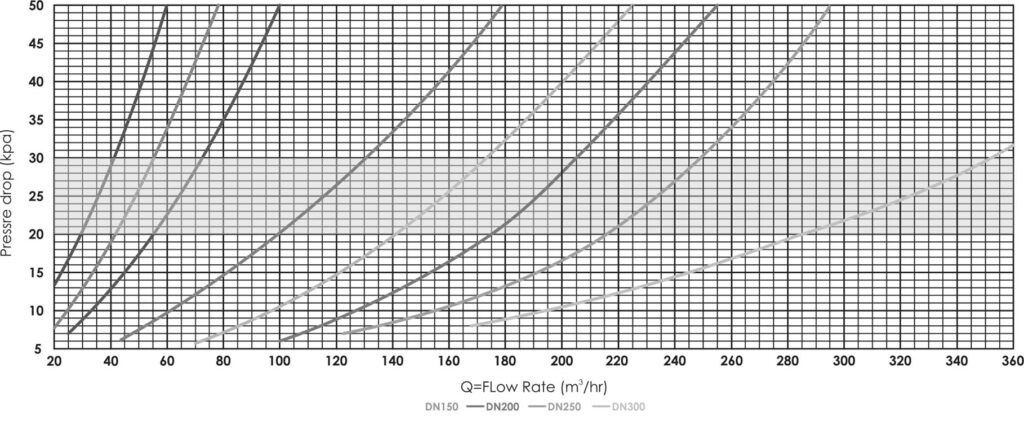

By providing the required fluid flow rate, the inlet and outlet flange sizes of the package are determined. Considering the typical installation constraints, the height of the device and the number of magnetic rods used are then specified. The model can be identified by the corresponding numbers.

Example: AMF_1072 means a 10-inch inlet and outlet with 72 magnetic rods.